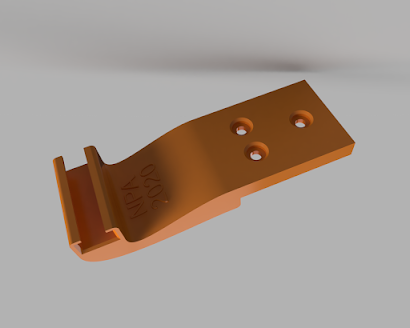

Nozzle cleaning station

Now released

I have now completed the testing of my nozzle cleaning station and it seems to be working very well

Nozzle Cleaning in action

If you have upgraded to Marlin 2.0 or later, the G12 command is available and you can simply use this to automate the process. If not, then you can easily create some movement GCODE and manually add this to your prints when you slice such that the clean can be incorporated.

The mount puts the brush head so that the nozzle can be around 1mm above the bed. The X and Y offsets are

X = Min to 10mmY = 140 to 185mm

Z = Min+1mm (although you might want to play with this)

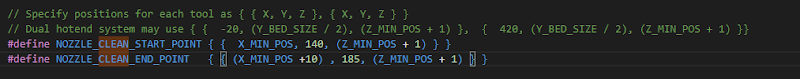

If you're setting up the G12 parameters in Marlin, I have used

For the brushes, I have used these from AliExpress, which are very cheap. I would like to think that many types of similar ones should fit. As you can see, I have simply cut off the bulk of the handle, but left a fair amount to use for replacing the brush.

Another consideration is the duct of the part cooling fan. You need to make sure that it doesn't come too low and foul the brushes, or modify your cleaning cycle to avoid it. In my case, I had designed my own duct as the others I'd tried had had various problems. This one does very slightly rub against the brush in use, but it isn't affected unduly.

Comments

Post a Comment