Update: A busy (but successful) day

Today, I have managed to complete quite a number of the tasks which I've been working on during the week. This includes

- Install new power rail splice

- Install new 5V power injector

- Install new enhanced LED bar

- Convert to dual Z axis drivers

- Create a new "turbo" version of my cooling nozzle

First, I created a new model for a rail-mounted power rail splice, using standard lever connectors. This is a very simple device, but one which seems to work very well. It's in two pieces:

The base holds a pair of standard lever connectors which slot in. The cables then just slot into each way (with a ferrule) and the lever holds it in place.

The other cables which splice into this can then be inserted

Once all of the cables are connected, there is a cover which both covers the device and also holds it in place to the extrusion

This then provides a very simple way to distribute 24V around the printer. If needs be, I can extend the design very simply to provide for larger connectors, although the end connector is only using 24AWG cable, so it can also have multiple cables into a single ferrule.

The purpose of this was to splice the power to the main board to provide power for the new 5V DC module for the LED bar upgrade.

This was done next. First a simple loom was created, to provide the necessary connections.

The board is held in place with three M3 screws

Once this was connected, it was simple to mount it to the vertical extrusion

This was then tested and everything worked fine on the first attempt. It was now providing the power to the LED bar, rather than the main board. It was then possible to fit the lid

This simply clips in place.I was moving from the top base (60 LEDs per metre - 19 in total) to the new one (144 LEDs per metre, 46 in total). the new base unit fits directly into the existing mount and diffuser, so it was just as case of re-assembling.

I had to make a minor change in Marlin to tell it the new number of LEDs and the recompile the firmware. Once this was uploaded, everything worked as expected. The lights were brighter and also more uniform as it now gave a single light source without being able to discern the individual LEDs.

This is all working well and I intend to leave it in this new configuration, albeit I do plan to add an additional LED on the extruder nozzle at some point.

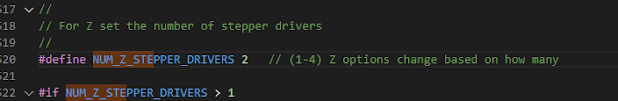

The next task was another I'd been planning for some time: to convert to dual Z stepper drivers. My SKR 1.4 Turbo mainboard has capacity for five steppers and I was only using four as the A8 Plus has a single extruder. So, I prepared and installed another stepper driver and then made three simple changes to Marlin

With only these three changes, the firmware was recompiled and worked first time. The only consideration is that it does clear the contents of the EEPROM, so this had to be manually uploaded again. I had taken a backup before the process anyway, so this wasn't a major problem. It was then possible (and simple) to run an automatic alignment of the Z axis.

In parallel with these changes, I have also been evaluating the cooling fan duct which I created some time ago. It was been working, but I thought that there was room for improvement. So, I have now created and new "turbo" version which has a smaller exhaust size and is aimed directly at the tip of the nozzle. I plan to run some bridging tests to see how much of a difference this makes.

And, of course, the other task I'm working on is creating sufficient chain links for my design for the X and Z axis cabling. I'm getting there

Comments

Post a Comment